Membrane Layer Switches Over Explained: A Comprehensive Guide to Their Advantages

Membrane layer changes represent a sophisticated and versatile option for producing individual interfaces across a selection of fields. As markets progressively look for trustworthy and effective control interfaces, comprehending the particular benefits and applications of membrane layer changes becomes crucial.

What Are Membrane Layer Switches?

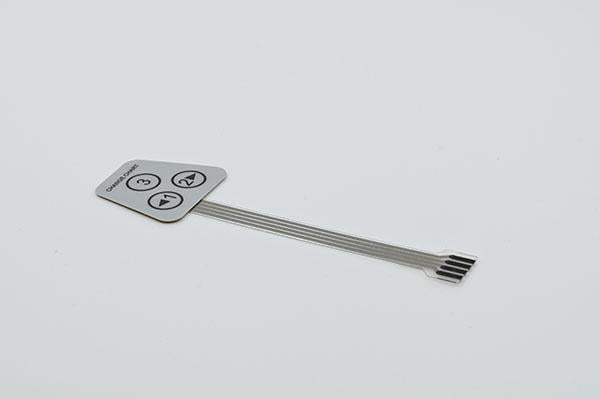

When pressure is put on the membrane layer button, the layers make get in touch with, completing an electrical circuit. This simple device permits a large range of applications, from consumer electronics to commercial equipment. Membrane switches are often designed to be resistant and waterproof to dust and pollutants, making them suitable for environments where durability is essential.

In addition, the versatility of the materials utilized in membrane switches over helps with cutting-edge styles that can comply with various forms and dimensions. This flexibility adds to their appeal in diverse areas, including clinical devices, vehicle controls, and home devices. In general, membrane layer switches stand for a crucial component in modern customer interface technology, linking the void between individuals and electronic systems.

Secret Benefits of Membrane Switches

Amongst the myriad of interface choices readily available, membrane changes stand apart for their special mix of advantages. One of the key advantages is their light-weight and compact style, which permits for combination right into a vast array of gadgets without including substantial bulk. This is particularly helpful in applications where room is limited.

Additionally, membrane changes deal resilience and resistance to environmental variables. They are generally created with products that can withstand wetness, dust, and different chemicals, making them ideal for rough problems. This resilience contributes to a much longer life-span contrasted to traditional mechanical switches.

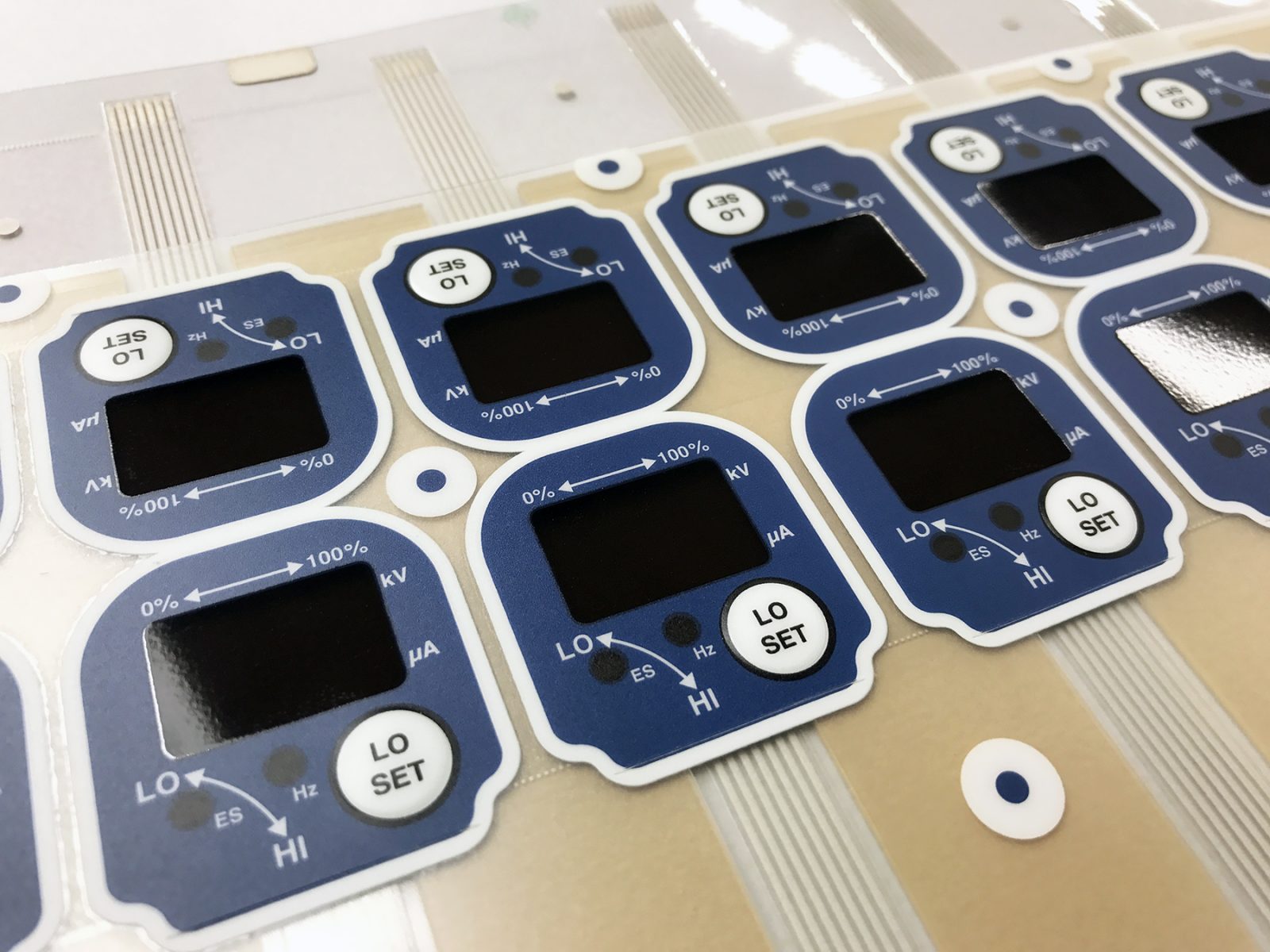

One more considerable benefit is the flexibility in personalization. Membrane switches can be printed with various graphics, shades, and appearances, enabling customized layouts that fulfill certain branding or practical demands. This versatility reaches the number of layers and circuit options, providing designers with numerous setups.

Furthermore, the tactile responses given by some membrane layer changes enhances customer experience, making them a lot more user-friendly to operate. The convenience of cleaning and maintenance further strengthens membrane buttons as a sensible option in both customer and industrial applications. Overall, these vital advantages make them a recommended option for numerous developers and producers

Applications in Various Industries

Exactly how do membrane buttons find their area across varied markets? Their adaptability and functionality make them indispensable elements in fields ranging from medical care to consumer electronics. In clinical devices, membrane buttons are made use of for their simplicity of cleansing and resistance to contamination, guaranteeing health in environments where sterility is important.

In the consumer electronics sector, these buttons offer streamlined, straightforward user interfaces that improve item looks while keeping sturdiness versus damage. Automotive applications gain from membrane switches also, where they are utilized in control panels and control board, offering dependable performance in difficult problems.

In addition, commercial equipment employs membrane switches for control panels because of their toughness, capacity to withstand harsh environments, and adjustable styles that accommodate certain functional requirements. The food market leverages membrane switches for their ease of use and resistance to spills, guaranteeing operational efficiency in fast-paced setups.

Inevitably, the adaptability of membrane layer switches over throughout these varied applications highlights their necessary function in contemporary technology, enhancing customer communication while satisfying industry-specific requirements. Their proceeded advancement guarantees further integration right into emerging fields and cutting-edge products.

Design and Customization Alternatives

The style and customization alternatives readily available for membrane buttons are critical for tailoring interfaces to satisfy particular customer demands and visual preferences. These buttons can be created in various forms, sizes, and designs, enabling smooth integration right into diverse applications. The versatility in design indicates that producers can develop distinct user interfaces that enhance use and maintain brand name identification.

Custom-made shades, graphics, and appearances can be put on the surface of the membrane layer switch, offering a possibility for branding and user interaction. In addition, backlighting options, such as LED lighting, can be included to improve exposure in low-light problems, thus improving performance.

Useful elements can likewise be tailored, including responsive responses and actuation force, which can be adapted to fit various customer interactions. The option of products, such as polyester or polycarbonate, allows for variants in resilience and environmental resistance, catering to the particular demands of different markets.

Inevitably, the comprehensive style and personalization abilities of membrane switches allow business to create user-friendly and visually enticing user interfaces, making certain that their items fulfill both visual and practical requirements efficiently. Membrane Switches.

Factors To Consider for Implementation

Implementing membrane changes calls for careful consideration of different factors to guarantee ideal capability and customer experience. Factors such as exposure to wetness, severe temperature levels, and chemical substances can significantly affect the switch's efficiency and long life.

Another important aspect is the button's style and design. Making sure that the responsive comments and actuation force align with user expectations boosts use. Performing customer testing can offer important insights into my company the optimal design.

In addition, compatibility with digital elements should be evaluated. The switch's wiring must line up with the overall system style, making certain trusted signal transmission and lessening interference.

Moreover, manufacturing techniques and costs should be examined. The option between personalized styles and basic models can lead and affect both budget plan time.

Last but not least, think about maintenance and fixing. Membrane switches might require certain cleaning and treatment procedures to preserve their appearance and capability in time. By addressing these considerations, companies can see post execute membrane layer switches that satisfy their operational requirements while providing a positive customer experience.

Conclusion

In verdict, membrane switches stand for a functional and long lasting control user interface appropriate for a broad range of applications throughout several industries. Membrane Switches. As modern technology proceeds to develop, the relevance of membrane layer switches in modern-day gadgets remains substantial, using both functionality and visual charm.

Membrane layer changes represent a functional and advanced solution for producing user interfaces throughout a variety of markets.Understanding the essential components of contemporary digital interfaces, membrane layer switches are a type of customer interface device that are composed of flexible, thin layers of product. In general, membrane layer switches represent a crucial aspect in modern-day user interface innovation, linking the gap between customers and digital systems.

Among the myriad of individual interface choices readily available, membrane changes stand out for their unique mix of benefits.The design and personalization options readily available for membrane layer switches are important for customizing user interfaces to official statement fulfill details individual needs and visual preferences.

Comments on “Discover the Advanced Styles and Personalization Options for Membrane Switches”